Copper is one of the most studied and widely used metals in engineering, construction, and MEP systems. Its properties make it indispensable for electrical wiring, plumbing, HVAC components, and architectural applications.

1. Physical Properties of Copper

Copper’s physical characteristics are what make it so valuable in electrical, thermal, and architectural applications.

Key Physical Properties

- Distinctive reddish‑orange metallic luster

- Excellent electrical conductivity (second only to silver among pure metals)

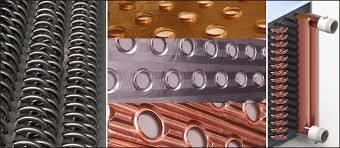

- High thermal conductivity — ideal for heat exchangers and HVAC coils

- Very ductile and malleable — easily drawn into wires or hammered into sheets

- Moderate melting point:

- (1357.77 K)

- Boiling point:

- (2835 K)

- Density:

- 8.96 g/cm³

- Corrosion resistance — forms a protective oxide layer in air

2. Mechanical Properties of Copper

Copper’s mechanical behavior makes it ideal for piping, wiring, and mechanical components.

Key Mechanical Properties

- High ductility — can be stretched into thin wires without breaking

- High malleability — can be shaped or rolled easily

- Good tensile strength (varies by alloy and temper)

- Tensile properties are detailed in engineering guides for copper alloys

- Excellent formability — suitable for extrusion, forging, and cold forming

- Good fatigue resistance — important for HVAC vibration environments

- Work‑hardening capability — copper strengthens when mechanically deformed

3. Chemical Properties of Copper

Copper’s chemical behavior is central to its corrosion resistance and antimicrobial performance.

Key Chemical Properties

- Common oxidation states: +1 and +2

- Reacts with oxygen to form:

- Copper(I) oxide (Cu₂O)

- Copper(II) oxide (CuO)

- Does not react with water, but slowly reacts with atmospheric oxygen to form a protective layer

- Forms green patina (copper carbonate) over time in moist air

- High corrosion resistance due to stable oxide films

- Acts as a catalyst in many chemical reactions

- Intrinsic antimicrobial behavior — scientifically validated and documented in copper alloy research

Summary Table:

| Property Type | Key Characteristics | Sources |

|---|---|---|

| Physical | High electrical thermal conductivity, ductile, malleable, corrosion‑resistant, moderate melting point | Copper mineral |

| Mechanical | Strong, formable, ductile, good tensile strength, work‑hardening | Copper Alloys |

| Chemical | Oxidation states +1/+2, forms oxides, corrosion‑resistant, catalytic, antimicrobial | Copper Catalysts |

Here are The Scientific Evidence That Copper Has Intrinsic Antimicrobial Properties

Modern research overwhelmingly confirms that copper and its alloys naturally kill bacteria, viruses, and fungi without needing chemicals or coatings. This antimicrobial action is intrinsic—it comes from the metal itself.

Below are the key scientific findings supported by peer‑reviewed studies and authoritative reviews.

1. Copper Generates Reactive Oxygen Species (ROS)

Extensive research shows that copper ions trigger the formation of reactive oxygen species, which damage microbial cells.

- Copper’s antimicrobial mechanism is “multifaceted,” with ROS generation being the main bactericidal mechanism, causing irreversible membrane damage.

- ROS attack lipids, proteins, and DNA, leading to rapid cell death.

Why this matters: ROS generation is a built‑in chemical property of copper—this is one of the strongest proofs that its antimicrobial activity is intrinsic.

2. Copper Ions Disrupt Cell Membranes

Copper ions penetrate and destabilize microbial membranes.

- Copper complexes “disrupt microbial membranes” and compromise membrane integrity.

- This leads to leakage of essential nutrients and rapid cell collapse.

Why this matters: Membrane disruption is a universal antimicrobial mechanism effective against bacteria, fungi, and viruses.

3. Copper Causes DNA and RNA Damage

Copper ions bind to and degrade genetic material.

- Copper complexes interact with DNA and proteins, causing DNA cleavage and enzyme inhibition.

- Copper ions released from surfaces lead to RNA degradation in viruses.

Why this matters: This explains why copper kills even antibiotic‑resistant bacteria and enveloped viruses.

4. Copper Destroys a Wide Range of Microorganisms

Historical and modern studies show copper kills bacteria, fungi, and viruses at extremely low concentrations.

- Copper inhibits numerous microbes including Bacillus, Candida, Aspergillus, and others, even at low concentrations.

- Some organisms are completely inhibited at concentrations as low as 0.04 g/L.

Why this matters: This broad‑spectrum activity is rare and demonstrates copper’s intrinsic toxicity to microbes.

5. Copper Alloy Surfaces Kill Pathogens on Contact

Scientists have repeatedly demonstrated that copper alloy “touch surfaces” destroy harmful microorganisms.

- Research confirms the intrinsic efficacy of copper alloy surfaces in killing a wide range of pathogens that threaten public health.

Why this matters: This is why copper is used in hospitals, transit systems, and high‑touch public environments.

6. The Oligodynamic Effect

Copper ions exhibit the “oligodynamic effect”—a toxic effect on microbes even at very low concentrations.

- The oligodynamic effect was identified in 1893 and applies to copper ions, which kill bacteria, fungi, spores, and viruses at low doses.

Why this matters: This effect is a fundamental chemical property of copper, not a surface treatment.

Summary: What Science Have Proven

Across multiple independent studies:

- Copper releases ions that damage membranes, DNA, and RNA.

- Copper generates ROS that kill microbes.

- Copper surfaces continuously kill bacteria and viruses.

- Copper works at extremely low concentrations (oligodynamic effect).

- Copper alloys retain antimicrobial activity indefinitely.

These findings confirm that copper’s antimicrobial behavior is intrinsic, natural, and scientifically validated.

1. Physical Properties of Copper

| Property | Value / Description |

|---|---|

| Appearance | Reddish‑orange metallic luster |

| Density | 8.96 g/cm³ |

| Melting Point | |

| Boiling Point | |

| Thermal Conductivity | 401 W/(m·K) |

| Electrical Conductivity | Very high (second only to silver) |

| Electrical Resistivity | 16.78 nΩ·m at 20°C |

| Thermal Expansion Coefficient | |

| Crystal Structure | Face‑centered cubic (FCC) |

| Heat of Fusion | 13.26 kJ/mol |

| Heat of Vaporization | 300.4 kJ/mol |

| Molar Heat Capacity | 24.44 J/(mol·K) |

| Magnetic Behavior | Diamagnetic |

| Color | Red‑orange / reddish‑gold |

2. Mechanical Properties of Copper

| Property | Value / Description |

|---|---|

| Tensile Strength | Moderate (varies by alloy and temper) |

| Yield Strength | Moderate (increases with work‑hardening) |

| Ductility | Very high — easily drawn into wires |

| Malleability | Very high — easily shaped or rolled |

| Hardness | Soft to moderately hard (depends on temper) |

| Elastic Modulus | ~110–128 GPa |

| Shear Modulus | ~48 GPa |

| Poisson’s Ratio | ~0.34 |

| Fatigue Resistance | Good — suitable for vibration environments |

| Impact Resistance | Moderate |

| Work‑Hardening | Strong — copper becomes harder when deformed |

3. Chemical Properties of Copper

| Property | Value / Description |

|---|---|

| Atomic Number | 29 |

| Atomic Symbol | Cu |

| Common Oxidation States | +1, +2 |

| Reactivity with Oxygen | Forms Cu₂O and CuO |

| Reaction with Water | Does not react with pure water |

| Reaction in Air | Forms protective oxide layer; develops green patina over time |

| Corrosion Resistance | High — stable oxide films prevent degradation |

| Antimicrobial Behavior | Intrinsic; copper ions disrupt microbial membranes and DNA |

| Catalytic Activity | Acts as a catalyst in many reactions |

| Solubility | Insoluble in water; soluble in acids like nitric acid |

| Electronegativity | 1.90 (Pauling scale) |

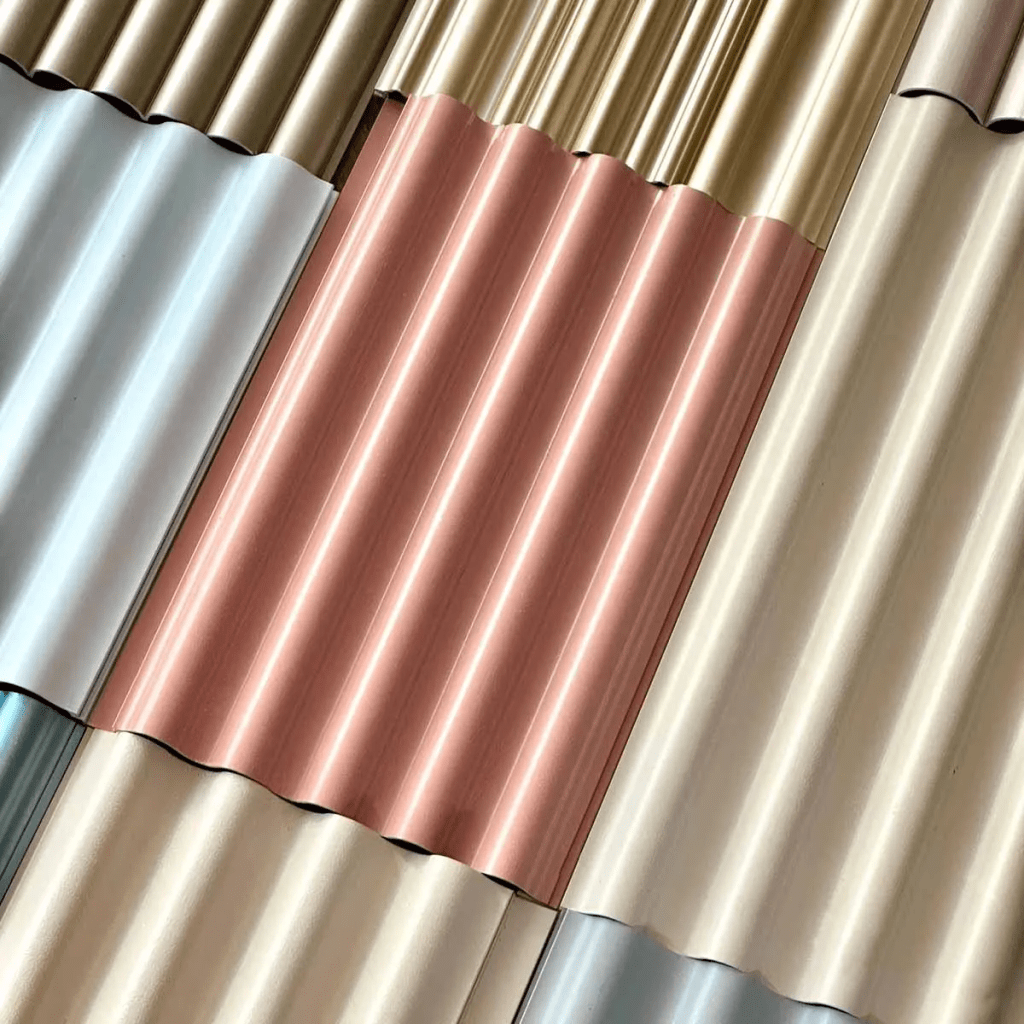

Here are Five Alloys Widely Used in MEP construction, HVAC and Architectural Applications

Properties of Five Common Wrought Copper Alloys

Table: Physical, Mechanical & Chemical Properties of Common Wrought Copper Alloys

| Alloy | UNS Number | Composition | Key Physical Properties | Key Mechanical Properties | Key Chemical Properties |

|---|---|---|---|---|---|

| C11000 – Electrolytic Tough Pitch (ETP) Copper | C11000 | ~99.9% Cu | High electrical & thermal conductivity; density 8.96 g/cm³ | Tensile strength ~200–250 MPa; excellent ductility & formability | Oxidizes to Cu₂O/CuO; high corrosion resistance; antimicrobial |

| C12200 – Phosphorus‑Deoxidized Copper (DHP) | C12200 | Cu + small P | High thermal conductivity; good weldability | Tensile strength ~200–250 MPa; good ductility; excellent tube formability | Resistant to hydrogen embrittlement; stable oxide layer |

| C26000 – Cartridge Brass | C26000 | 70% Cu, 30% Zn | Good thermal conductivity; golden color | Tensile strength ~300–500 MPa; high ductility; good cold‑working | Good corrosion resistance; susceptible to dezincification in harsh environments |

| C28000 – Muntz Metal | C28000 | 60% Cu, 40% Zn | Good conductivity; higher strength than C26000 | Tensile strength ~350–550 MPa; good hot‑working | Better corrosion resistance than typical brasses; forms protective oxide |

| C70600 – 90/10 Copper‑Nickel | C70600 | 90% Cu, 10% Ni | Moderate conductivity; excellent seawater resistance | Tensile strength ~275–380 MPa; good toughness; good weldability | Exceptional resistance to seawater corrosion, biofouling, and stress corrosion |

Common Copper Alloys: Composition & Key Properties

Table: Composition & Properties of Major Copper Alloys

| Alloy Name | UNS Number | Typical Composition | Key Physical Properties | Key Mechanical Properties | Key Chemical Properties |

|---|---|---|---|---|---|

| ETP Copper (Electrolytic Tough Pitch) | C11000 | ~99.9% Cu | Very high electrical & thermal conductivity; density 8.96 g/cm³ | Tensile strength ~200–250 MPa; excellent ductility; soft to moderately hard | Forms Cu₂O/CuO; high corrosion resistance; antimicrobial; stable oxide layer |

| Oxygen‑Free Copper (OFHC) | C10200 | 99.95% Cu, very low O₂ | Highest electrical conductivity among copper alloys; excellent thermal conductivity | Tensile strength ~220–260 MPa; high ductility; excellent formability | Extremely low oxygen prevents embrittlement; excellent corrosion resistance |

| Phosphorus‑Deoxidized Copper (DHP) | C12200 | Cu + 0.015–0.040% P | High thermal conductivity; good weldability; non‑sensitive to hydrogen | Tensile strength ~200–250 MPa; good ductility; ideal for tubing | Resistant to hydrogen embrittlement; stable oxide film |

| Cartridge Brass | C26000 | 70% Cu, 30% Zn | Good thermal conductivity; golden color; moderate density | Tensile strength ~300–500 MPa; excellent cold‑working; high ductility | Good corrosion resistance; may dezincify in harsh environments |

| Muntz Metal | C28000 | 60% Cu, 40% Zn | Good conductivity; higher strength than C26000 | Tensile strength ~350–550 MPa; good hot‑working | Forms protective oxide; better corrosion resistance than typical brasses |

| Aluminum Bronze | C95400 | ~85% Cu, 10–11% Al, 3–4% Fe | High strength; good thermal conductivity; bronze color | Tensile strength ~500–700 MPa; excellent wear resistance | Exceptional corrosion resistance, especially in seawater |

| Silicon Bronze | C65500 | ~97% Cu, 2.8–3.8% Si | Good conductivity; high corrosion resistance | Tensile strength ~350–550 MPa; good toughness; good formability | Excellent resistance to atmospheric and chemical corrosion |

| 90/10 Copper‑Nickel | C70600 | 90% Cu, 10% Ni | Moderate conductivity; excellent seawater resistance | Tensile strength ~275–380 MPa; good weldability; good toughness | Outstanding resistance to seawater corrosion and biofouling |

| 70/30 Copper‑Nickel | C71500 | 70% Cu, 30% Ni | Lower conductivity; very high corrosion resistance | Tensile strength ~350–500 MPa; high strength; good fatigue resistance | Superior resistance to erosion, stress corrosion, and seawater |

Brief Summary of Copper and Its Alloys

Copper and its alloys stand out as some of the most reliable and durable engineering materials used in modern construction and MEP systems. Their exceptional mechanical strength, corrosion resistance, and long service life make them ideal for demanding environments ranging from residential plumbing to large‑scale commercial HVAC and electrical infrastructure. Copper’s excellent formability allows it to be drawn, rolled, extruded, or shaped into complex components without losing structural integrity, supporting efficient manufacturing and installation.

Beyond performance, copper is inherently sustainable. It is 100% recyclable without any loss of properties, enabling a fully circular material lifecycle that reduces environmental impact. Its intrinsic antimicrobial behavior—a natural ability to deactivate bacteria, viruses, and fungi—adds a unique health and safety advantage, especially in high‑touch or high‑traffic environments.

Copper alloys such as brasses, bronzes, and copper‑nickels expand this versatility even further. By adjusting alloying elements like zinc, tin, aluminum, or nickel, engineers can tailor strength, corrosion resistance, conductivity, and wear performance to meet specialized requirements. This combination of reliability, durability, sustainability, formability, and intrinsic functional benefits is why copper and its alloys remain foundational materials across the built environment.

One thought on “The Physical, Mechanical and Chemical Properties of Copper”