Many studies are taken place to best improve the durability of modernized old and new construction commercial and residential buildings. These studies include materials necessary to resist varying catastrophic and harsh climate conditions.

1. Structural Materials

These form the backbone of any building—whether a home, office, or industrial facility.

Concrete

- Most widely used material for foundations, slabs, columns, beams, and floors.

- Strong, durable, moldable, and cost-effective.

- Made from cement, water, sand, and aggregates.

- Source: Concrete is consistently listed as the top essential material.

Steel

- Used for reinforcement (rebar), framing, beams, and large-span structures.

- High tensile strength and flexibility—critical for commercial buildings.

- Source: Steel is highlighted as a key structural material.

Wood

- Common in residential framing, flooring, roofing, and interior finishes.

- Renewable, lightweight, and naturally insulating.

- Source: Wood is a core material for residential and light commercial builds.

Bricks & Blocks

- Used for walls, partitions, facades, and load-bearing structures.

- Fire-resistant and thermally efficient.

- Includes clay bricks, concrete blocks, and formwork blocks.

- Source: Concrete blocks and formwork blocks are essential items in modern construction lists.

2. Foundation & Earthwork Materials

Aggregates (Sand, Gravel, Crushed Stone)

- Used in concrete mixes, mortar, drainage layers, and site leveling.

- Also used directly as underlays for slabs and landscaping.

- Source: Aggregates are essential for forming, filling, and shaping.

Cement & Binders

- Cement acts as the binder in concrete and mortar.

- Other binders include natural resins and lime.

- Source: Binders are listed as core construction materials.

3. Exterior Envelope Materials

These materials protect the building from weather and define its appearance.

Glass

- Used for windows, facades, skylights, and storefronts.

- Modern glass options include tempered, laminated, insulated, and low‑E.

- Source: Glass is indispensable for light-filled buildings.

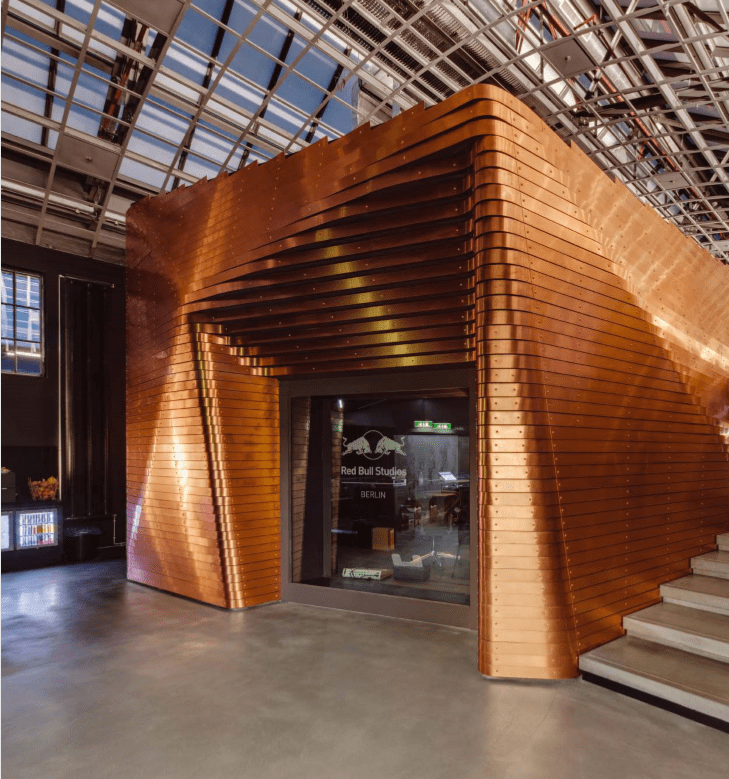

Siding & Cladding Materials

- Options include vinyl, fiber cement, metal panels, stone veneer, and brick veneer.

- Chosen for durability, insulation, and aesthetics.

Roofing Materials

- Asphalt shingles (residential)

- Metal roofing (commercial & residential)

- EPDM/TPO membranes (commercial flat roofs)

- Clay tiles, slate, composite shingles

4. Interior Construction Materials

Drywall / Gypsum Board

- Used for interior walls and ceilings.

Insulation

- Fiberglass, spray foam, rigid foam, cellulose.

- Critical for energy efficiency and comfort.

Flooring Materials

- Concrete, tile, hardwood, vinyl, carpet, laminate.

Paints, Finishes & Sealants

- Used for protection, aesthetics, and moisture control.

5. Mechanical, Electrical & Plumbing (MEP) Materials

Pipes & Fittings

- PVC, PEX, copper, cast iron.

Electrical Components

- Wiring, conduits, panels, switches, outlets.

HVAC Materials

- Ductwork, insulation, vents, mechanical units.

6. Modern & Sustainable Materials

Increasingly important in both commercial and residential projects.

Composite Materials

- Fiber-reinforced polymers, engineered wood, structural insulated panels (SIPs).

- Source: Composite materials are highlighted as essential modern options.

Recycled & Eco-Friendly Materials

- Recycled steel, reclaimed wood, recycled aggregates.

- Low‑VOC paints, green insulation, solar panels.

Summary Table:

| Category | Key Materials | Best For |

|---|---|---|

| Structural | Concrete, steel, wood, bricks/blocks | Foundations, framing, load-bearing elements |

| Foundation | Aggregates, cement | Slabs, leveling, concrete mixes |

| Exterior | Glass, siding, roofing | Weather protection, aesthetics |

| Interior | Drywall, insulation, flooring | Comfort, layout, finishes |

| MEP | Pipes, wiring, HVAC components | Utilities and building systems |

| Sustainable | Composites, recycled materials | Energy efficiency, modern builds |

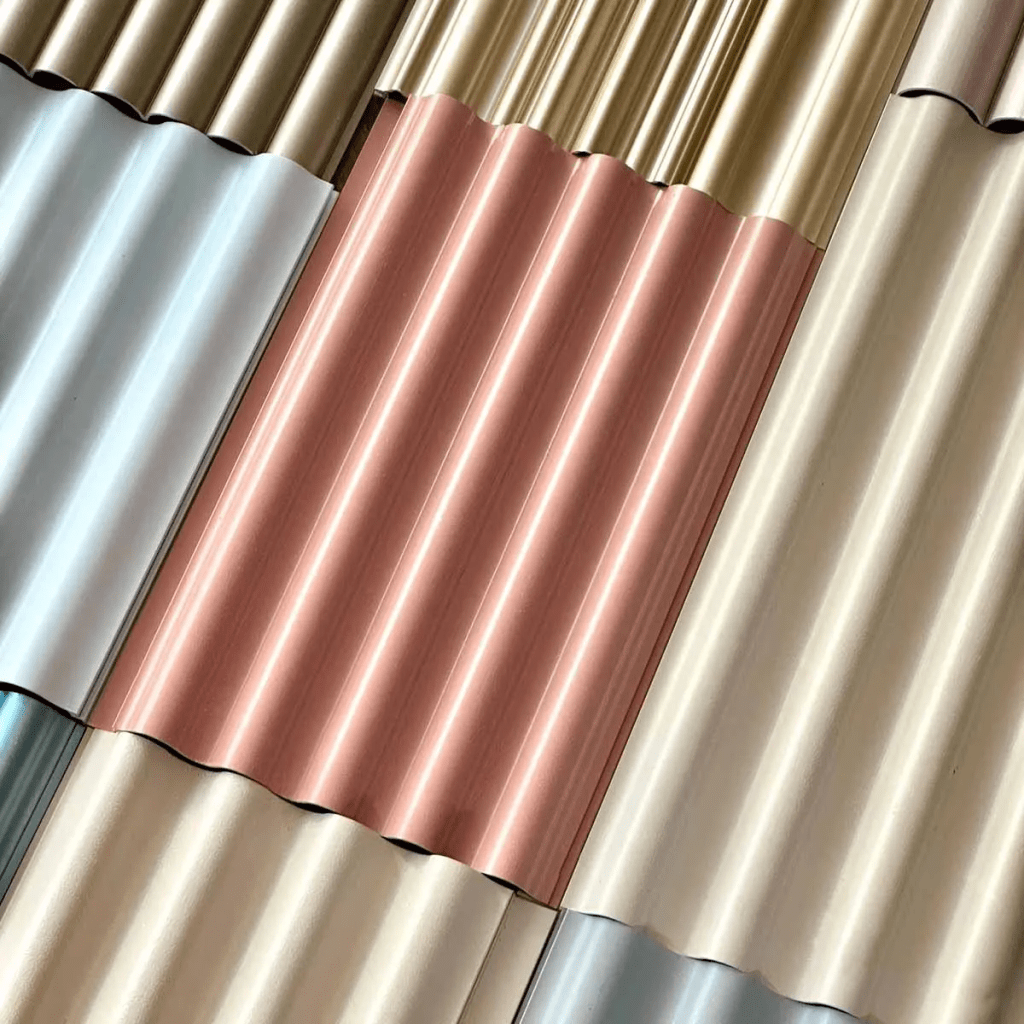

How Effective Are Copper Alloys in MEP Systems?

Copper alloys are among the most durable, reliable, and high‑performance materials used in mechanical, electrical, and plumbing (MEP) systems. The research you surfaced highlights several reasons why copper alloys remain the gold standard for pipes, wiring, and HVAC components.

Below is a structured explanation grounded in the sources you triggered.

1. Exceptional Electrical & Thermal Conductivity

Copper and its alloys have industry‑leading conductivity, which is why they dominate electrical wiring and HVAC heat‑exchange components.

- Copper’s electrical and thermal conductivity is highlighted as one of its defining advantages.

- High conductivity means:

- Less energy loss in wiring

- More efficient heat transfer in HVAC coils

- Better performance under load

This is why copper remains the preferred material for electrical wiring, busbars, and HVAC coils.

2. High Corrosion Resistance

Copper alloys resist corrosion extremely well—even in harsh environments.

- The Copper Development Association notes that copper alloys have strong resistance to corrosion and stress corrosion cracking.

- This makes them ideal for:

- Plumbing pipes

- HVAC coils

- Outdoor mechanical systems

- Marine or coastal installations

Copper alloys form a protective oxide layer that prevents long‑term degradation.

3. Fire Resistance & High‑Temperature Stability

Copper alloys maintain strength and conductivity even at elevated temperatures.

- Research shows copper alloys retain mechanical and electrical properties under thermal stress.

- This makes them safer and more reliable for:

- Electrical wiring

- Fire‑rated systems

- High‑temperature HVAC components

Unlike plastics, copper does not melt, burn, or release toxic fumes.

4. Mechanical Strength & Durability

Copper alloys offer a strong balance of strength, ductility, and formability.

- Tensile and mechanical properties are well‑documented across hundreds of copper‑based alloys.

- This allows copper alloys to:

- Withstand pressure in plumbing systems

- Resist vibration and fatigue in HVAC systems

- Maintain structural integrity over decades

This is why copper pipes often last 50–100 years in buildings.

5. Antimicrobial Properties (Bonus Advantage)

Copper has natural antimicrobial behavior.

- The Copper Development Association highlights copper’s intrinsic antimicrobial properties and EPA‑validated performance.

- This is especially beneficial in:

- Hospitals

- Schools

- High‑touch mechanical systems

While not the primary reason for MEP use, it’s a valuable added benefit.

6. Sustainability & Recyclability

Copper alloys are 100% recyclable without losing performance.

- Sustainability and recyclability are emphasized in modern copper alloy research.

- This supports:

- LEED certification

- Circular construction practices

- Long‑term material efficiency

Copper is one of the most recycled metals in the world.

Summary Table: Why Copper Alloys Excel in MEP Systems

| Performance Area | Effectiveness of Copper Alloys | Pros. on MEP Systems |

|---|---|---|

| Electrical conductivity | Excellent—industry leading | Longer service life |

| Thermal conductivity | High—ideal for HVAC coils | Improved energy consumption |

| Corrosion resistance | Strong—protective oxide layer | Reliable power distribution |

| Mechanical strength | High—supports pressure & vibration | Durable piping and reliable fittings |

| Fire resistance | Non‑combustible, stable at high temps | Easy to bend, braze, solder, and join |

| Antimicrobial | Proven EPA‑validated behavior | Cleaner potable water, healthier indoor environments |

| Sustainability | Fully recyclable, eco‑efficient | Supports green building goals and material circularity |

Impact on MEP Systems

| Performance Area | Why Copper Alloys Excel | Impact on MEP Systems |

|---|---|---|

| Corrosion Resistance | Naturally resists oxidation, pitting, and chemical attack | Longer service life, fewer leaks, reduced maintenance |

| Thermal Conductivity | High heat-transfer efficiency | Better HVAC coil performance, improved energy efficiency |

| Electrical Conductivity | Among the highest of all engineering metals | Reliable power distribution, lower energy loss |

| Mechanical Strength | Strong across wide temperature ranges; maintains integrity under pressure | Durable piping, reliable fittings, fewer mechanical failures |

| Formability & Workability | Easy to bend, braze, solder, and join | Faster installation, easier retrofits, reduced labor complexity |

| Antimicrobial Properties | Inhibits bacterial growth and biofilm formation | Cleaner potable water, healthier indoor environments |

| Fire Resistance | Non-combustible; high melting point; no toxic fumes | Safer electrical systems, compliance with fire codes |

| Compatibility | Works well with standard fittings, solders, and joining methods | Predictable performance and easier system integration |

| Longevity | Proven multi-decade lifespan in real-world installations | Lower lifecycle cost and fewer replacements |

| Sustainability | 100% recyclable without performance loss | Supports green building goals and material circularity |

Bottom Line:

Copper alloys are extremely effective for MEP systems because they combine:

- High conductivity

- Corrosion resistance

- Mechanical durability

- Fire safety

- Long service life

- Sustainability

This makes them one of the most reliable materials for pipes, wiring, and HVAC components in both commercial and residential buildings.

In certain locations the readiness of raw materials is industrialized and incorporated within the budget for building adequate buildings reducing on-site maintenance costs. The production of these materials creates more jobs for builders, exploiting expansions of industrial plaza, residential areas and shopping plazas keeping communities engaged within those areas.

Major projects accommodating education, transportation, and Community centers pursuits in these locations.